30May2025

Announcement / Highlight content / Latest News & Report

Comments: No Comments.

Despite initial operational challenges, OEVN has steadily grown and now plays a vital role in supporting its parent company. This case study, shared with the company’s consent, provides valuable insights for businesses planning market entry into Vietnam or facing difficulties during early expansion.

The Pre-establishment in Vietnam

– Okamoto Corporation began in 1971 as a small screw factory in Yono City (now part of Saitama City). Under the leadership of the second-generation president, Mr. Tomonori Okamoto, the company with about 30 people and specializes in ultra-precision metal and plastic parts using lathes.

– By 2010, although domestic operations were stable, internal challenges surfaced. The founder had retired to become chairman in 2002, leaving the company to the current president. However, there were issues within the company. There was friction between the older employees who had been retained from the previous generation and the younger generation. The older employees, who were several decades older than the younger generation, were reluctant to teach the younger employees much, while the younger employees showed no interest in learning from them. Communication within the company and the transfer of skills were insufficient, making it difficult to make progress on new initiatives. The president felt the need to bring in some fresh air, so he decided to utilize the technical internship program .

– In 2012, the first two trainees were hired from Vietnam, and the number gradually increased the following year. The effect was great. The trainees, who asked questions openly and frankly and showed a willingness to learn, brought vitality to the factory and spread a willingness to teach.

– The system required trainees to return to their home countries after three years. This meant that there was nowhere for the trainees to go after training them. So, the company decided to establish a Vietnamese corporation .

Operations in Vietnam

Traditionally, industrial parks in Vietnam have been based on a 50-year land lease system, and the model was that companies would build their own factories. Only large plots of over 10,000 square meters were available, and depending on the location, the cost of acquiring land and building a factory can run into the hundreds of millions. As more and more small and medium-sized enterprises move into the area, rental factory services, which involve renting plots inside already-built factories, have been gaining popularity as a lower-risk option.

The company started a Vietnamese factory in 2013 with five employees and five machines in a rented factory in the Khai Quang Industrial Park in Vinh Phuc Province. The aim was not to increase sales or profits at this factory. If the returning trainees were made employees of the Vietnamese corporation, they could be transferred to Japan. This would make it possible to utilize the Vietnamese employees that had been trained beyond the three-year limit for technical intern trainees.

Due to the limited scale and purpose, there was no pressure to operate the plant, and the first goal was to establish stable operations. The staff, mainly trainees who had returned to Japan, worked hard to establish daily operations , and the production line slowly began to move. However, the annual sales were only about 6 million yen, which was far from a recovery in the investment.

The turning point for this leap came two years after the company was founded , when Makito Okamoto (current president ) was hired from outside the company . Incidentally, President Okamoto in Japan is the chairman of the local subsidiary. The two men are not related and it is only a coincidence that they have the same last name, but to avoid confusion, I will refer to them as Chairman Okamoto and President Makito.

When he joined the company, President Makito was 35 years old and had several years of experience working at a Japanese manufacturing factory in Vietnam. His wife was Vietnamese and he could speak Vietnamese, making him an ideal candidate. He was selected from many other candidates and was eager to start the company from scratch. However, when he joined the company, he was shocked to find that sales were only about 800,000 yen per month. The chairman told him to take it easy, but he honestly thought, “There’s no way they’re paying me that much.”

To overcome this situation, we first tackled reforms at the site. The Vietnamese team had a leader and was diligent, but they were inexperienced and many issues remained. In addition, the company’s management system, such as accounting, was insufficient, and there were issues that spanned both the site and management, such as inventory management. We solved these issues one by one.

Real growth

On the other hand, increasing sales is a top priority. In addition to Chairman Okamoto and President Makito, sales specialists were hired and deployed.

When considering the company’s growth, there is no doubt that strong sales power is a major factor. The essence of sales power is the development of new projects through collaboration between sales, technology, and production. New projects require new technology, and often require capital investment. Without knowing for certain whether sales will actually take off or be sustained, the company must take risks and invest, or it will miss out on opportunities. Various subsidies from the Japanese government and local governments have also been utilized to reduce risk.

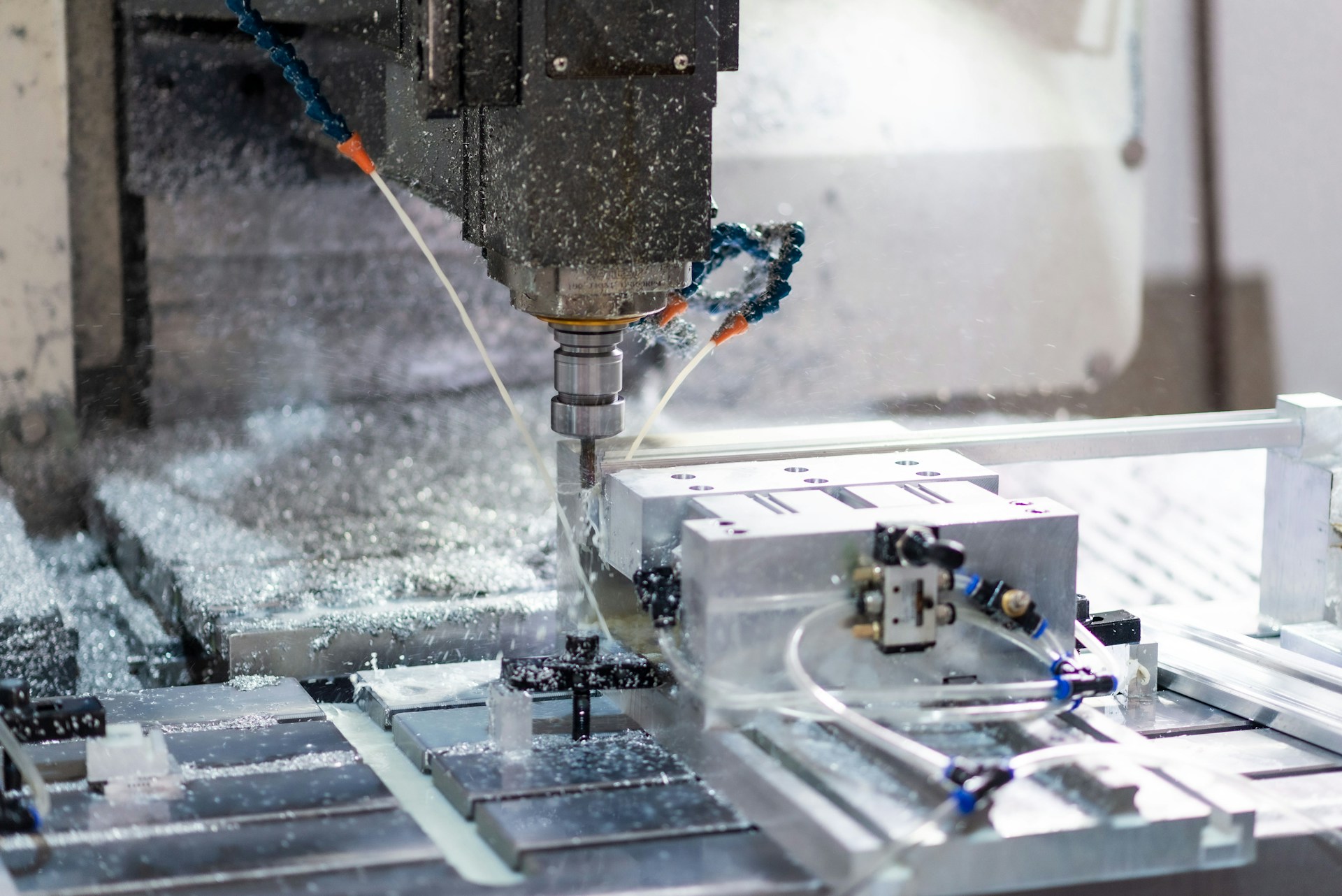

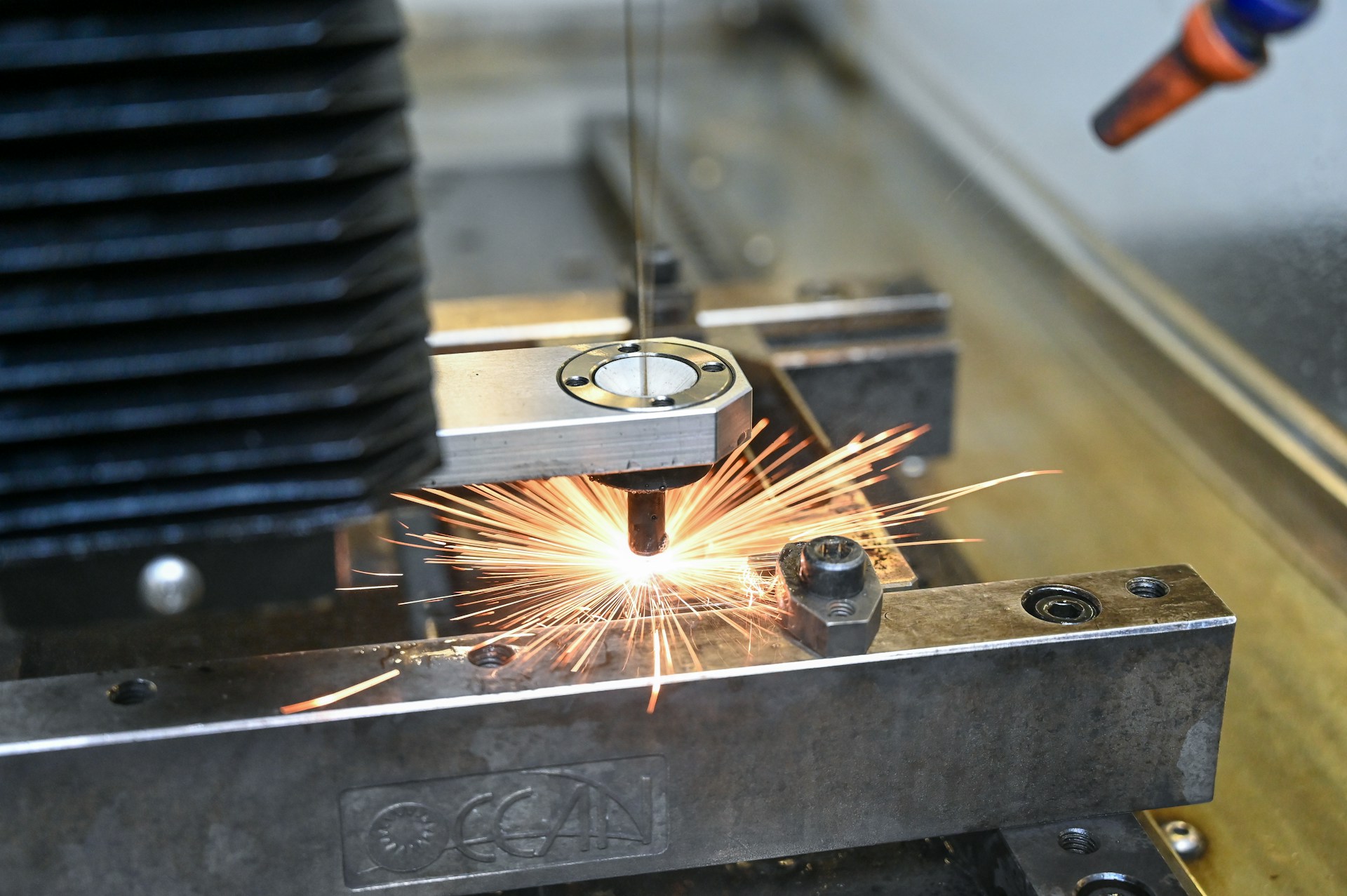

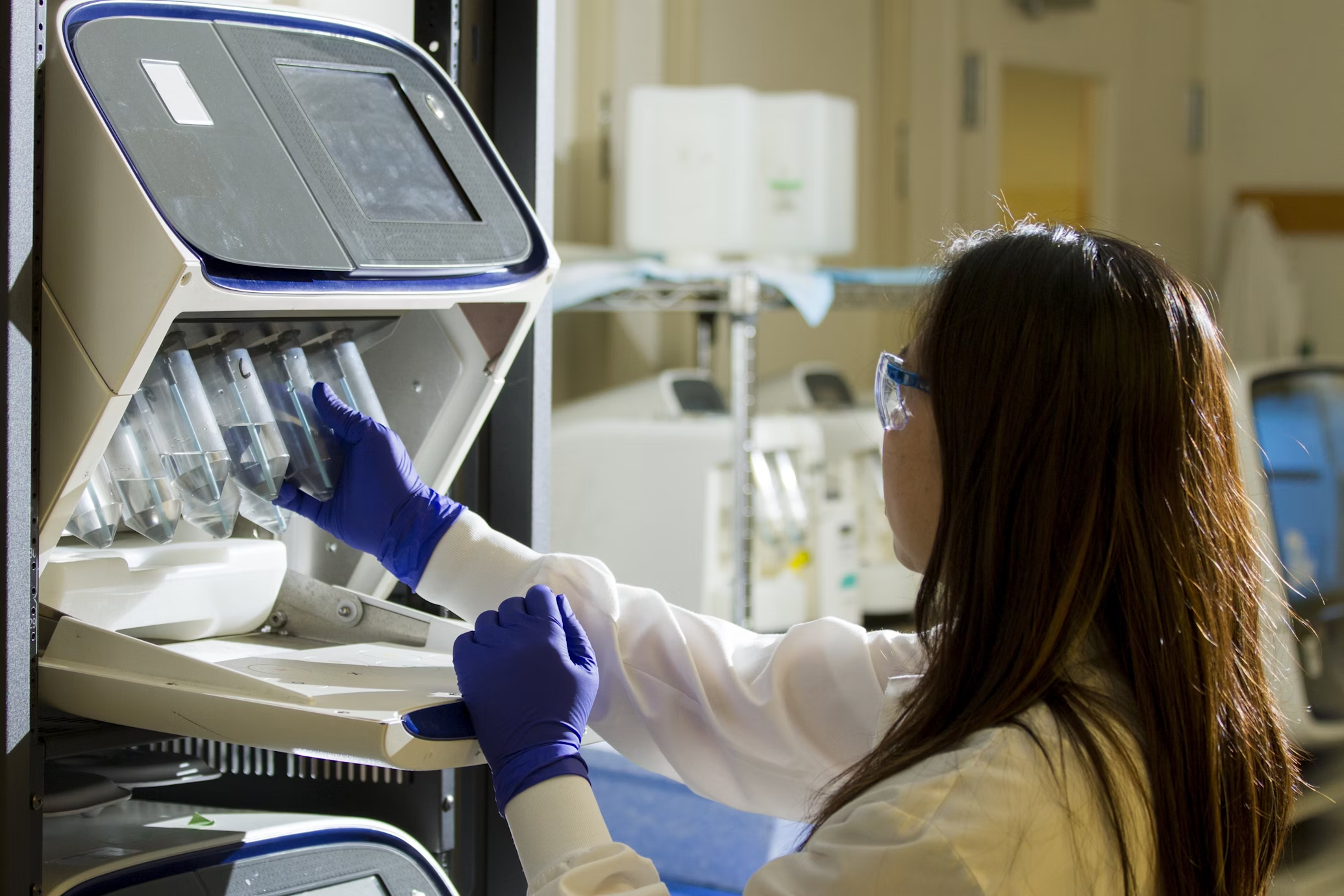

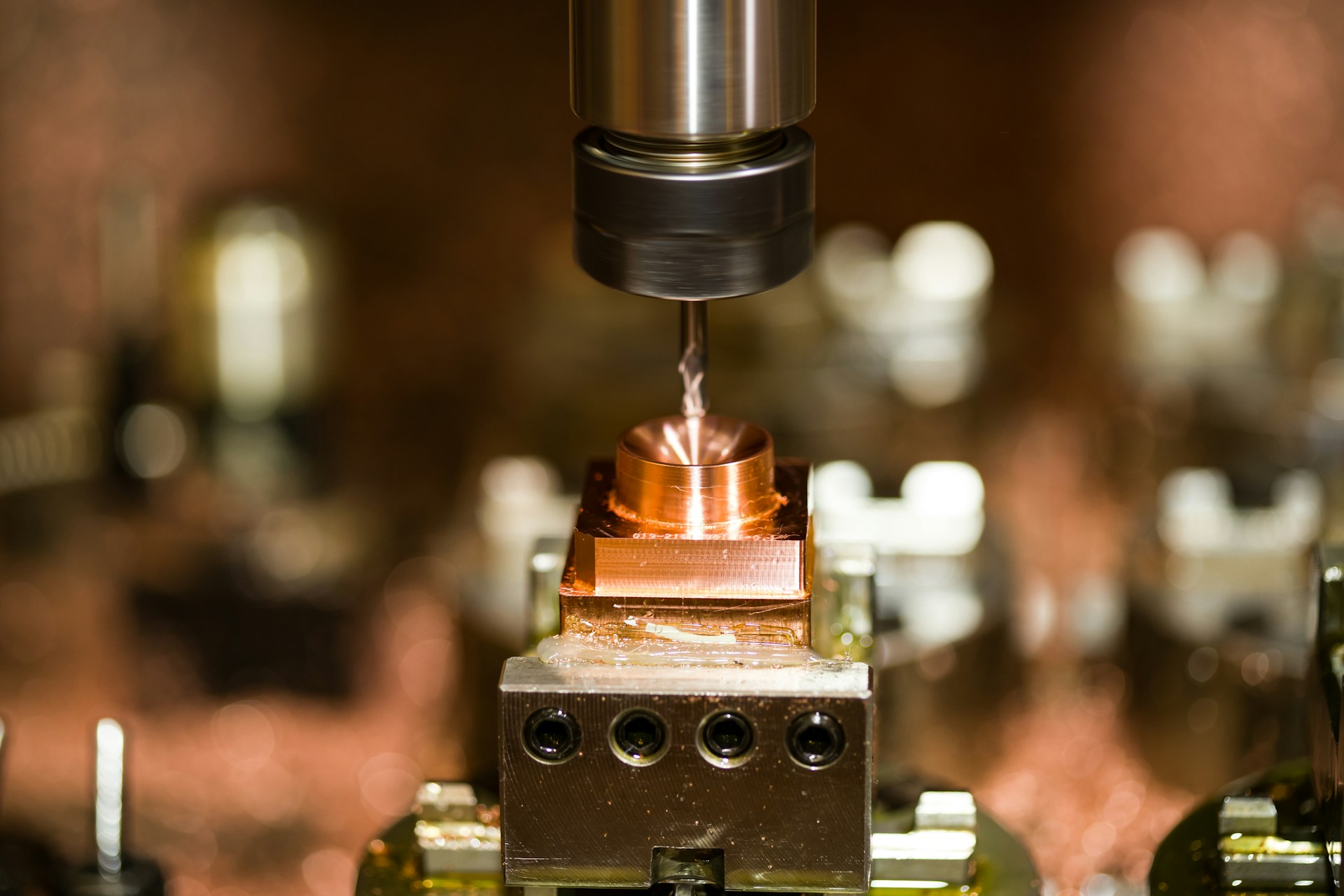

The company’s main products are precision metal parts, but they can differentiate themselves by producing particularly precise and difficult parts. Their customer industries include optics, hobby, and medical, but the end users are often B2C. For this reason, they need to release new products every year to stimulate customer purchasing desire. New functions, shapes, and specifications are required, which is both a business opportunity and a challenge for parts manufacturers. By responding to these demands, the amount of work they receive will expand every year.

As a result, the organization expanded dramatically from its small beginnings to eventually surpass the parent company in terms of personnel.

Support from B&Company

B&Company has supported OEVN for 10 years since it first entered the market. Since it was an advisory contract, the issues they handled were wide-ranging, but some of the early issues they handled included the following:

- Organizing accounting operations

The business management operations that were outsourced to a local accounting firm in the early stages. The company handled the switchover carefully to gain the cooperation of the accounting firm, but the transition took time, and created missing documents.

- Addressing accounting issues

The large amount of loans from Japan caused various management issues. Profits were subject to fluctuations due to exchange rate gains, and a repayment plan to the Japanese subsidiary was required. For this reason, borrowing was incorporated into capital. Inventory management was also difficult issue. There were many irrational tax accounting rules unique to Vietnam, which took time to resolve.

- Responding to stricter environmental regulations

Environmental regulations were strengthened at the time, and we had to prepare the necessary documents and deal with the authorities.

- Human resources support

Designing recruitment criteria and methods for executive personnel and supporting implementation such as interview participation, establishing wage and evaluation systems, resolving labor issues, etc.

Resolving management issues is important in order to focus on sales and production, but it also has other benefits. Correct management produces useful information, and using this information creates a virtuous cycle.

” It helps to have visibility into how much profit each customer is bringing in, and how each investment contributes to cash flow and profits .”

President Makito looks back on the time.

Utilizing corporate databases

There are many things that parts manufacturing companies cannot do in-house, and they need many partner companies. This is especially true when new initiatives are required. Initially, OEVN relied on public directories and chance encounters to find these companies. Currently, OEVN uses the company database of B&Company.

B& Company’s E-DB began operation in 2018, and data for the eight years from 2016 to 2023 is currently available (for more information, click here ). 900,000 companies, including Japanese companies, are divided into approximately 500 industries, making it possible to extract candidate companies.

We also succeeded in identifying potential partner companies and business partners that you could not have identified on your own. This was particularly useful when searching for partners in specific fields such as the plating industry.

Ripple effects on Japanese corporations and future prospects

The company’s growth in the area is also reflected in the numbers . Currently, the factory floor area has expanded to approximately 2,400 square meters . There are 75 machines and 89 employees , both of which are more than 10 times the original number . There have been periods of recession when sales and profits stagnated, but the company has been able to overcome these by continuing to take on new projects.

So what happened to Japanese corporations while Vietnam grew? With the Japanese economy stagnating, the idea of compensating for the shrinking Japanese market by expanding overseas may be the perspective of large corporations. In fact, the results are often different for small and medium-sized enterprises.

In the case of Okamoto, the organizational structure of the Japanese headquarters was strengthened around the time of entering Vietnam, and the number of employees at the Japanese subsidiary increased by 1.5 times compared to when it first entered the country, and sales also grew similarly.

Of particular note is the customer base that the company has acquired locally . Transactions with customers acquired in Vietnam have been realized in Japan as well, leading to increased sales for the Japanese subsidiary. The increase in activity based in Vietnam has created a synergistic effect in sales between Japan and Vietnam.

Meanwhile, the young staff newly hired from Vietnam brought with them an energetic and lively work ethic . As mentioned above, they breathed new life into the existing company culture and revitalized the overall atmosphere . This is an example of how entering Vietnam has been a major step in management, leading to improved productivity on the ground and revitalization of the entire business .

* If you wish to quote any information from this article, please kindly cite the source along with the link to the original article to respect copyright.

| B&Company

The first Japanese company specializing in market research in Vietnam since 2008. We provide a wide range of services including industry reports, industry interviews, consumer surveys, business matching. Additionally, we have recently developed a database of over 900,000 companies in Vietnam, which can be used to search for partners and analyze the market. Please do not hesitate to contact us if you have any queries. info@b-company.jp + (84) 28 3910 3913 |